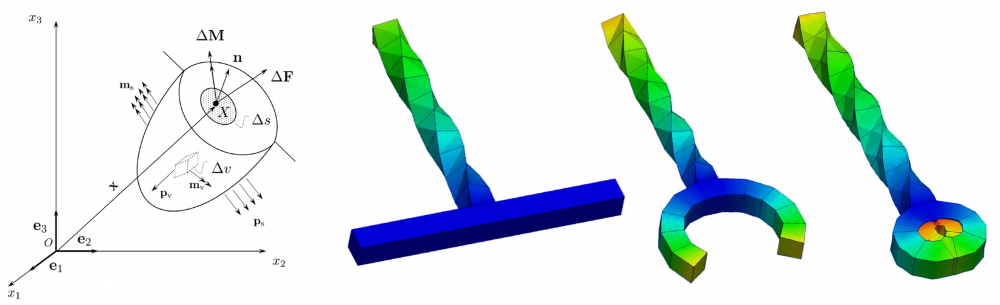

Analysis of a 3D printed samples (PLA) was performed in order to determine the modulus of elasticity and Poisson’s ratio. Dimensions of the samples are according to the norm ISO 3167 and they were printed with a 3D printer Prusa I3 MK3 owned by the Faculty. The first group of experiments consists of two types of samples, which differ in structure, i.e. in the direction of printing (0° and 45° in respect to the samples’ axis). The specimens were subjected to a tensile test in a Zwick 600 testing machine. Surface deformations were recorded with the GOM Aramis optical measurement system.

The structure of the first group of samples

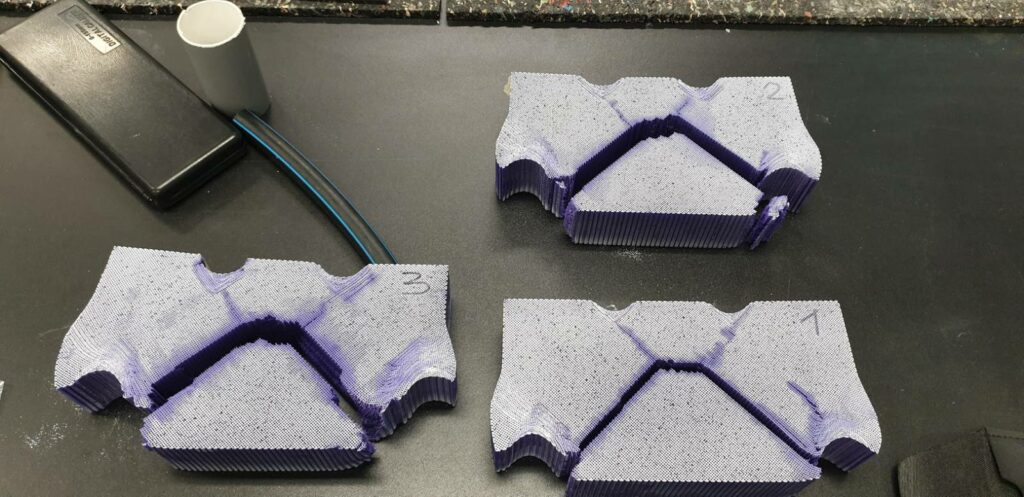

The samples after the fracture

After determining the modulus of elasticity and Poisson’s ratio, prisms of identical material (microstructure corresponds to the previous samples) were 3D printed with dimensions 24x12x5 cm. A four-point bending test was performed on the Controls testing machine and the deformations and fractures occurring on the prisms were analysed in detail with the optical measurement system software.

Sample model in AutoCad

Sample structure

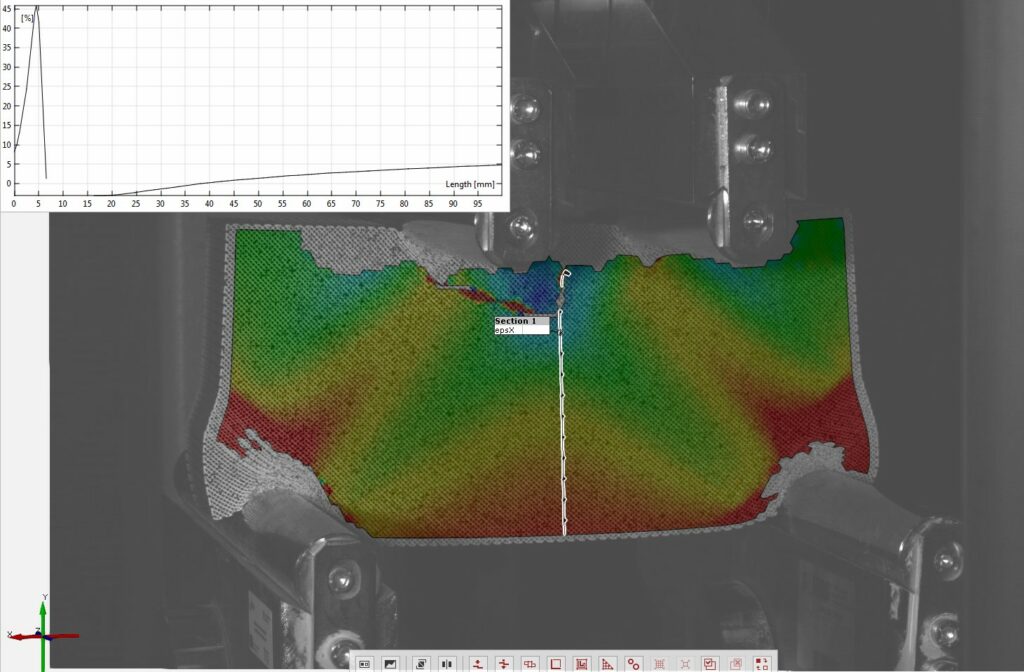

Four-point bending test

Deformation monitoring

Samples after testing

This experiment is the part of the undergraduate thesis project of our student Antonio Milevoj under the supervision of Assistant Professor Edita Papa Dukić.