We want to capture a size effect phenomenon that manifests itself in increased stiffness of smaller specimens made of the same material (which is not recognized in the classical theory). For this reason we have a different size of aluminium specimens with artificially created micro-structure and in today’s experiment we have a smallest one. The dimensions of specimens are 150×12,7×12,7 mm and unfortunately this is too small for our Controls hydraulic testing machine. That is why this time we had an experiment in the Center for Micro- and Nanosciences and Technologies, Laboratory for Precision Engineering and Micro- and Nanosystems Technologies with the valuable help of doc. dr. sc. Ervin Kamenar.

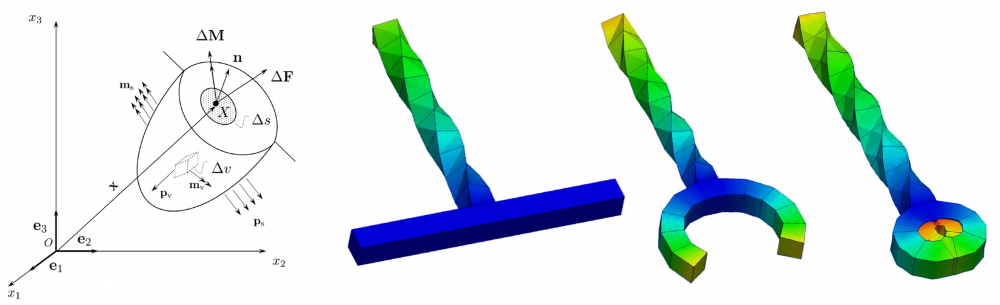

The aluminium specimen with artificially created micro-structure

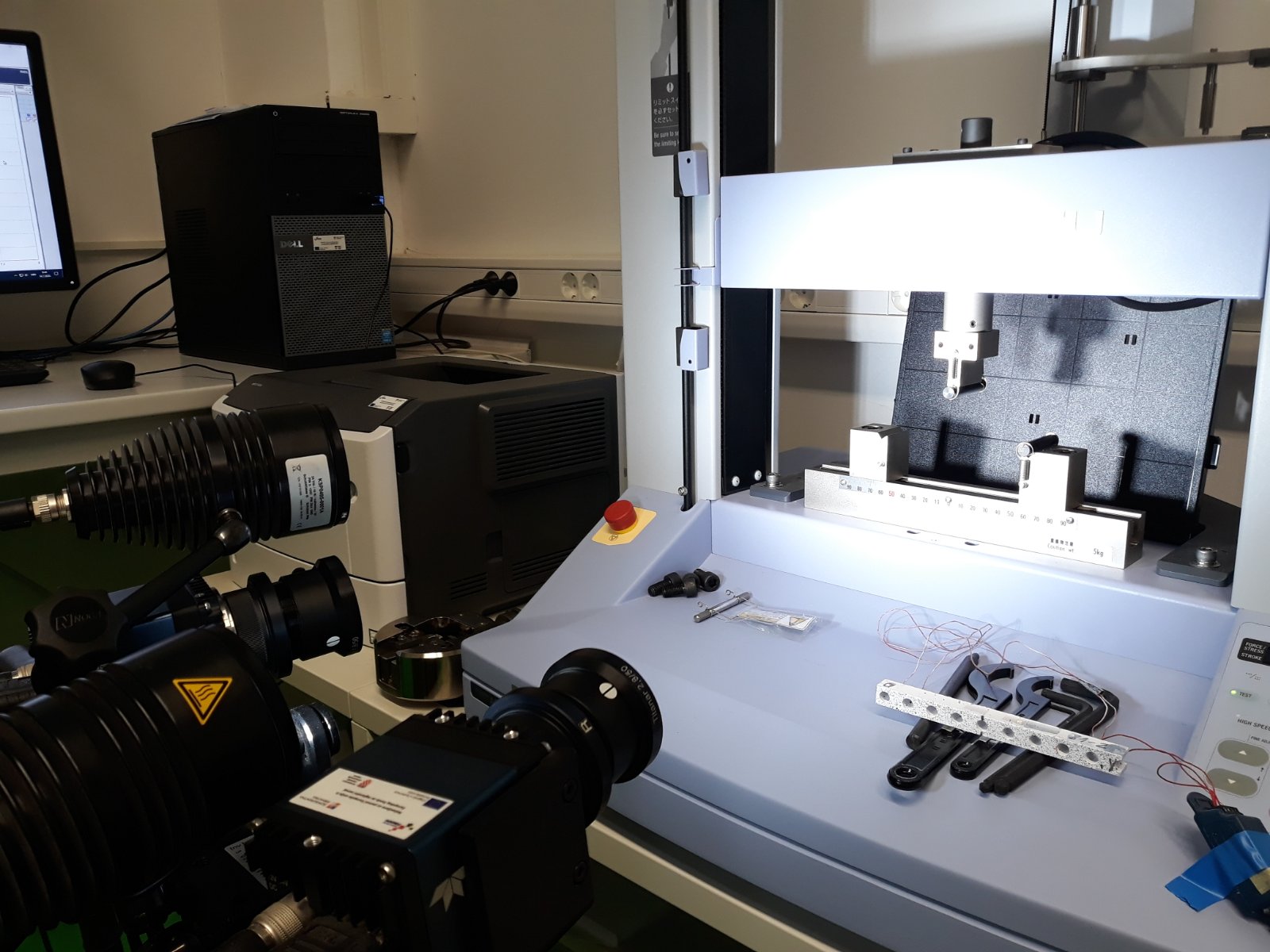

Our 4th group of experiments took place on 13th and 14thof July 2020. The aluminium specimens were subjected to a three-point bending on Shimadzu Autograph AGS-X testing machine (5 kN) using dedicated data processing software (TRAPEZIUM LITE X).

Shimadzu Autograph AGS-X testing machine

Specimen setup on testing machine

Sneak peek

We are all ready

Three-point bending test

We monitored deformations at the specific points of the specimens via strain gauges and also, the experiments have been video recorded using specialised GOM Aramis software for strain measurement.